Process Control & SCADA

Largest District Cooling SCADA World-Wide

Process Control & SCADA

End User: Empower Energy Solutions

Location: Dubai, UAE

Start Date: July 2014

End Date: July 2016

Brief

Empower promotes energy-efficient practices that are key to the fundamental growth and future of Dubai. The company was created with the objective of providing world class District Cooling Services (DCS) to Dubai in general and Dubai Holding entities in particular.

The purpose of the project was to meet the critical needs of stakeholders and future-proof the networked system to minimize disruption and maintenance costs.

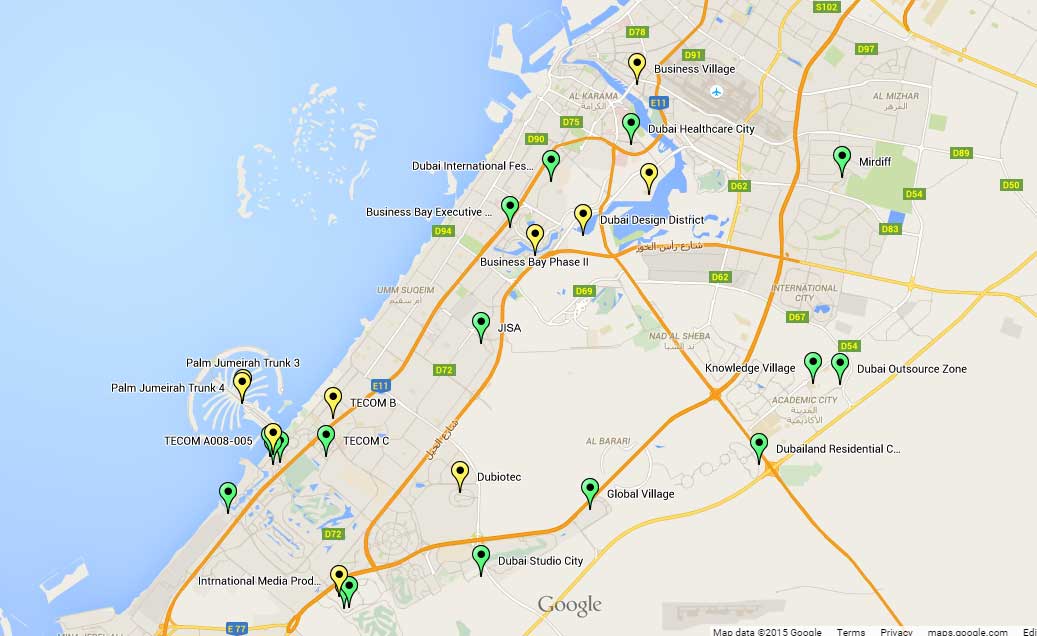

Avanceon, in close partnership with Rockwell, proposed to construct a command & control center at Empower to connect the entire district cooling network spread through nine sites including JBR, TECOM, DIFC and Business Bay to name a few. Empower Emirates Central Cooling System Cooperation awarded the contract to one of the leading system integration engineering firms. The first phase completed and shown in green as well as the second phase in yellow illustrate the breadth of the project.

Project Scope

360-degree Central Command and Control SCADA and District Cooling Network Integration Solutions

Centralized FactoryTalk virtualized SCADA system delivers Industrial Internet of Things [IIoT]

Fully virtualized Industrial Data Center (IDC) hosting redundant FactoryTalk SCADA servers, FactoryTalk Historian, extensive reporting and KPIs using FactoryTalk Vantage Point, MPLS based connectivity, secure communication network based on Stratix distribution switches and CISCO core switches, voice annunciation of alarms at all plants including SMS and email service of alarms, GSM based Siemens remote telemetry solution.

Solution

The overall system functionality of the District Cooling Command & Control Center project was mainly divided into three layers as below:

Command & Control Center SCADA

Network Layer

District Cooling Plants – Data Collection & Mode Control

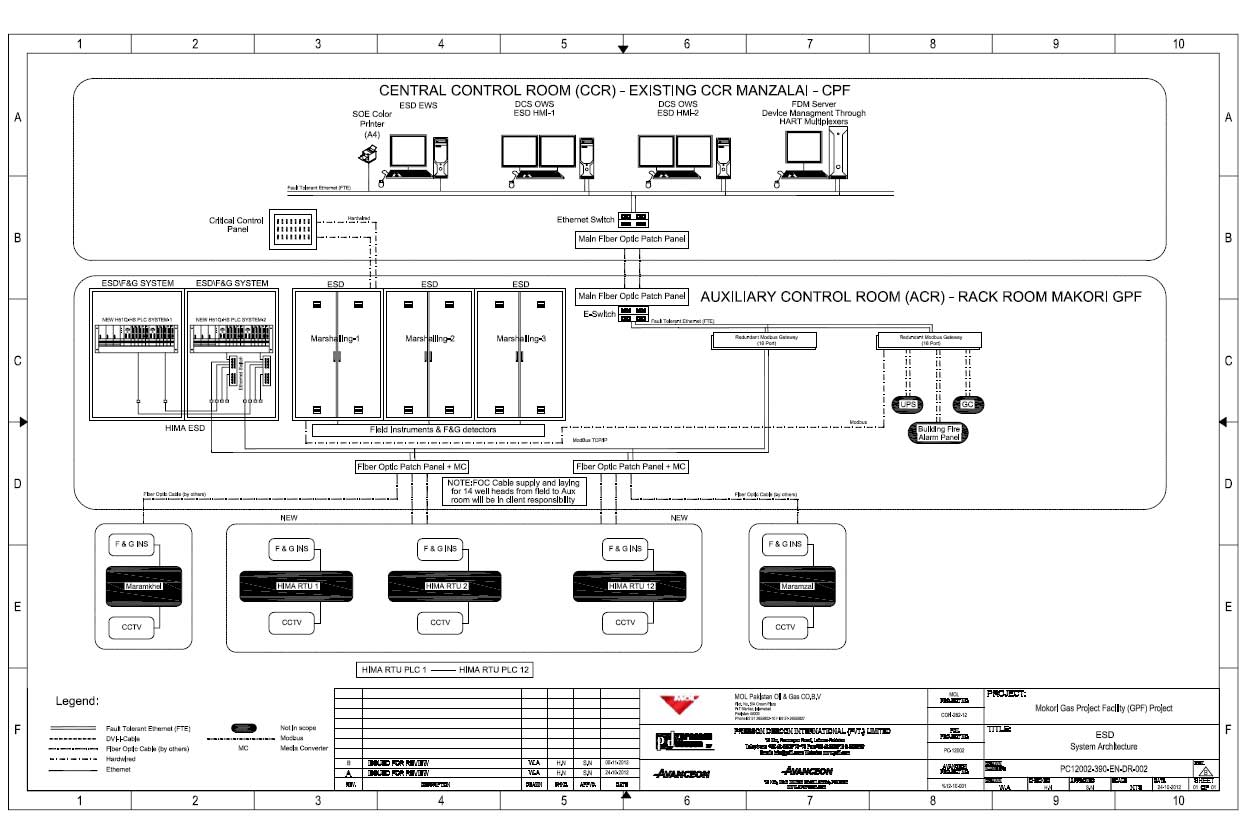

The CCC SCADA was hosted on four physical servers which in turn had to host the Virtual Servers used for CCC SCADA deployment. The physical servers were sized as per the project specifications and also meet the requirements for running all the SCADA Virtual machines and leaving enough resources to configure High Availability options for virtual machines in case of physical server failure. Command & Control layer of is the top most layer of the system and comprises CCC SCADA Servers, Clients, Storage and Video Wall. Figure below shows the topology of the command and control center.

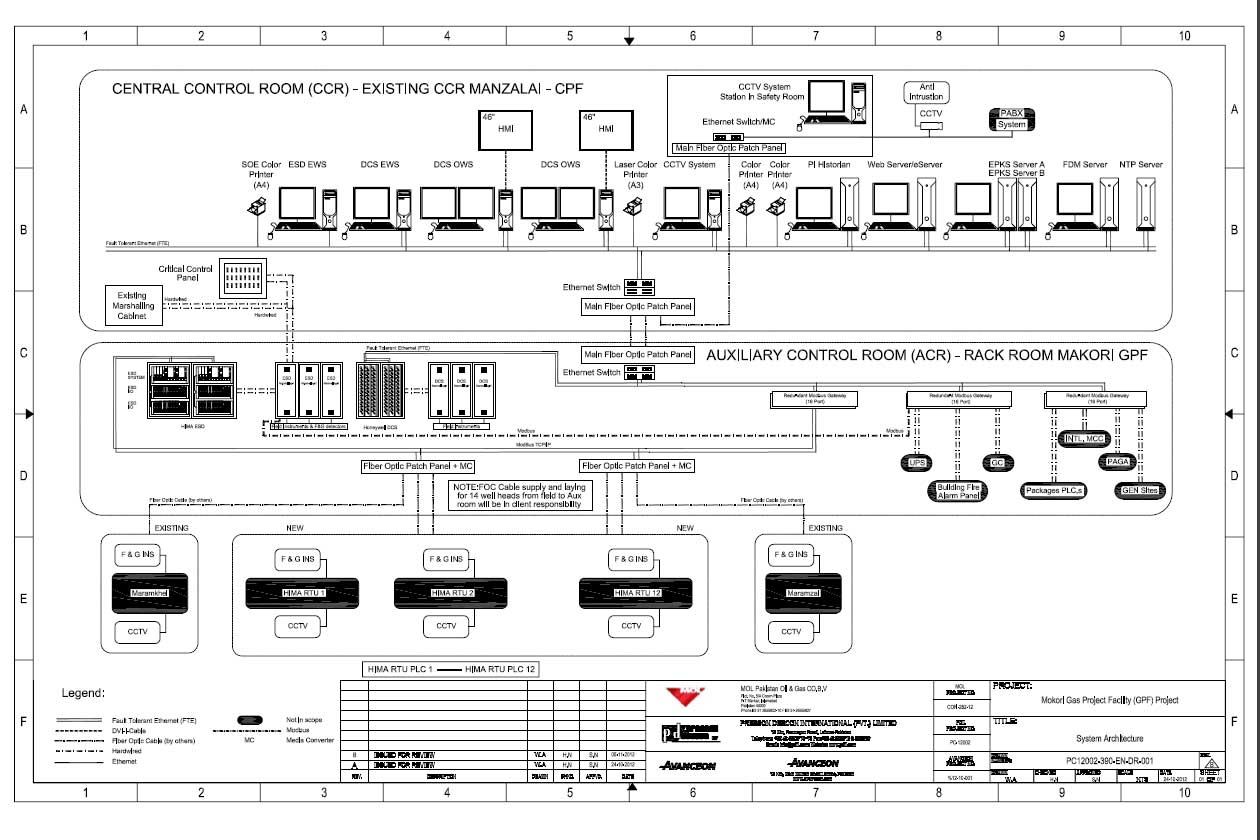

The Network Layer is responsible for the data communication between the DC Plants and the CCC. Each DC Plant shall be provided with a Managed Ethernet Switch and a VPN Router to establish the link between the Plants and CCC. In between the Plants and CCC is an MPLS network provided by Du network. MPLS along with the CCC SCADA data is also being utilized for corporate network. The network is segregated using separate Virtual LANs for CCC SCADA and Corporate Network. The figure below shows the typical communication path for data connectivity between DCPs and CCC.

Server Virtualization for the CCC SCADA System was designed to optimize the system resource usage and also optimize the space requirements inside the Central Command & Control Room with a number of Virtual Servers residing on the four physical servers. VMware’s Virtualization technology was integrated along with advanced features like High Availability.

VMware’s High Availability (HA) technology has been provided to minimize the Mean Time Between Failure (MTBF). In case a Physical server fails, the HA pairs of the configured virtual machines running on the server immediately start booting up on another physical server to take their place. The physical servers shall have enough resources to shift all the virtual machines to the available physical server.

Command & Control Center SCADA used FactoryTalk. All the DCP data was displayed on the SCADA screens on individual thin clients. The HMI Screens displayed the data from all DCP Plant PLCs in real time. The Metering SCADA were provided to display the metering data on the SCADA Clients.

The CCC SCADA system was provided with a complete Historian package which allowed the data from all DCPs to be historized at a central location. The Historian Interface Nodes on each Data Server in the DCPs poll data from the Field devices and send the filtered data to the Historian for archiving and for use in Reporting. The FactoryTalk Historian used advanced compression algorithms to archive the data in highly compressed format and interpolate the historized values when required by reporting tools.

Result

Awarded on July 7 2014, the project was scheduled to be deployed within the next 5 months. As part of their commitment towards the community, the three forward-thinking market leaders are teaming up to implement world-class Process Control & optimization solutions based on Rockwell Automation’s best-in-class OSISoft PI solution.

This seamless solution was to streamline district cooling in the emirate for years to come. This is also one of the World’s largest SCADA Systems in the District Cooling Sphere.

Clients' Review

“We are proud to be invited to deploy our leading technologies in yet another groundbreaking project in a key market for us with trusted industry partners. Rockwell are enthusiastic to be involved in an integration solution of this magnitude that will positively impact the residents of Dubai,”

Murray Ballantyne

Regional Director at Rockwell Automation